Good to know

A zirconium frame from the final sintering “ages” approximately for two years until reaches its final material structure. During that process it can loses even 40% of its strengths, thus high quality material is crucial, as well as adequate static planning of circular bridges and bridges’ critical points during the designing of the frames, so the thickness of the material can provide appropriate stability in the long run too. For that purpose, we provide highly qualified professionals, certifications and proper materials.

Medical preparation of zirconium frames

- The tooth stumps have to be at least 3 mm high measured from the mucous membrane.

- Between the scraped stump’s occlusal surface and the antagonist tooth’s surface, there is a 1.5-2 mm interspace is necessary, since zirconium crowns in case of lateral bridges have to be 0.6-0.7 mm thick. The most aesthetic result can be achieved through unified 1.2 mm thick veneering.

- In case of frontal teeth, depending on status, the thickness of the zirconium crown can be 0.4-0.5 mm, the veneering’s 1.2 mm again.

- Bridging is mostly appropriate for the lateral prosthetics of two missing molar, occasionally for three as well, when the height of tooth abutments’ stumps are at least 5 mms high measured from the crest.

If the plaster model made from the impression is adequate, the preparation of the plaster model can be started which is the most fundamental part of the work, and that is the basis of the further methods and the accuracy of the product.

After that based on the dental procedure, we prepare the prosthesis and work it up on the model to be the most accurate. If we prepare the porcelain veneering, and frame trial is also necessary, we send the work back to the dentist before the veneering for the test.

The finished work with the spoon and the plaster model is sent back on the agreed date.

Preparation

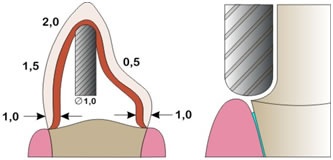

When it is possible, try to make shoulder preparations; at least 1.0 mm shoulder is recommended, but it is better to exceed that number. The ideal width of a shoulder is between 1.5 and 2 mms.

That width is also necessary for the following 3 layers.

- The saturation of the bonding agent, expected width: 0.03-0.06 mms.

(It can be planned in CAD system, see: CAD/CAM technology) - The safe wall thickness at the front is 0.4 mm, at the molars is 0.5 mm. The CNC technology applied by us allows even 0.1 mm wall thickness, however nor in case of zirconium or titanium is it recommended to push these boundaries. Although, around the sensitive cervical area a little thinning (max. 0.2 mm) is allowed.

- The thickness of the opaque, the dentin and the light burning is approximately 0.5 mm.

Because of the scanning method of the 3D scanner, it is important to have at least 2-30 cone in the stumps from every angle, and that the line of the preparation is concentric, so the scanner's measurements are going to be more accurate which provide better fitting frame. Avoid the preparation of blade-like, thinned or sharp stumps, because in that case during the preparation of the crown, a very small milling has to be applied which increases the production time, the costs and the possibility of breaking tools. That is unwanted both for the dentist and the technician. Therefore aim for at least 1-2 mm rounded tips.

When it's possible, make 2 phase impressions with clearly visible contour lines on the shoulder, for this purpose, sulcus dilation is recommended.

Cementing the crowns

Zirconium is acid-fast, thus its surface cannot be scraped by acid-etching.

For conventional cementation, the following cements are suitable:

- Zink phosphate - (Harward, Richter&Hoffmann)

- Glasionomer - (Ketac Cem, 3M ESPE)

* The surface of the stump does not require special preparation before conventional cementation.

For adherence bonding, the followings are recommended:

- RelyXR Unicem

- 3M ESPE

- Panavia 21

- Panavia F

Conventional or adherence?

When you are aiming for well-distributed occlusal load, then it worth to choose adherence technology, since the abutment picks up the mediated pressure in full geometry, however in case of zirconium prostheses, this solution is not required because the material is strong enough in itself to hold the occlusal load, but it is still worth to strive for perfection. In addition inquiring the manufacturer about the recommended fixing technology can also be rewarding.