CAD CAM room

Our objective is providing affordable, quality services through the most up-to date technologies and qualified professionals. The lab's main activity is preparing zirconium, titanium and golden prostheses. We possess all necessary equipment required for preparation of final and full zirconium prostheses.

Prostheses made by CAD-CAM technology: zirconium, titanium and golden crowns and veneers.

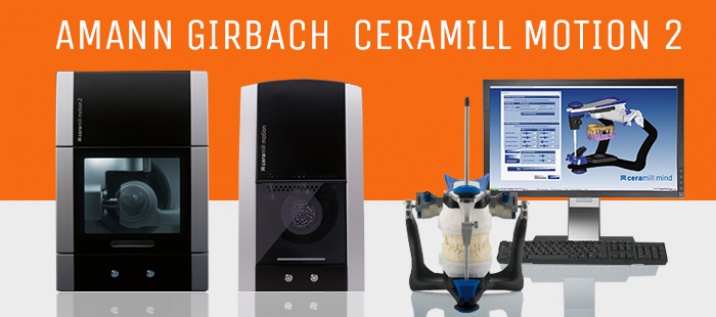

Main equipment:

- Computer

- 3D scanner

- 5-axis mill

- Artex articulator

Articulating system

Every technician have an own Amann Girbach Artex articulator. The articulators in the lab are standardized, therefore the distance of the lower and upper magnetic bases and the relation between the articulator axis and upper magnetic base are the same in all devices. The CAD/CAM scanner's built-in articulator has the same setting as well, but we can change those when requested.

We establish basis for precise and accurate work already at the beginning of work which is inevitable for excellent quality.

Drafting room

Main equipment

Paraskop M Neu multifunctional milling unit with Bece Air zirconium turbine

- Use: Milling and drilling of wax and metal, machining zirconium dioxide.

- Vibration-free.

- Powerful, manintenance-free, brushless micromotor.

- Progressive speed control up to 50000 rpm, counter-clockwise up to 30000 rpm – provides for adequate power reserves.

Turbine

- A compact and powerful laboratory turbine with a 2 litre tank.

- Applicable on the new Paraskop M.

Drufosmart deep drawing unit

- Suitable for foils with a material thickness between 0.1 mm and 5.0 mm.

- Easy time settings due to semi-automatic operation.

- Digital and acoustic control of heating and cooling phase.

- Axiomatic operator keyboard, extensive information on monitor.

- Overheat protection with automatic switch-off of the heater after heating time has expired.

- Working pressure: 2.5 bar.

Veneer room

Ceramic furnaces

Beside Degudent's different ceramic furnaces which can be applied well in case of the company's Duceram Kiss metal and Cercon Ceram KISS metal-free veneering ceramics, we use Dekema's pressable ceramics furnace for the Emax - Press technique developed by Ivoclar Vivadent. Thereby, we can prepare solo inlays, unique implants and crowns or even alter the pressing of full bridges.

Our veneering ceramics: DeguDent Duceram Cercon KISS

Vita vPad comfort/excellence/clinical

- Control unit for VITA VACUMAT 6000 M and 6000 MP combipress oven and VITA ZYRCOMAT 6000 MS

- VITA vPad comfort / clinical control unit: 7 "color touch screen, storage for 500 programs 1GB Photo Viewer and 2 sintering, cauterization or combipress oven control.

- VITA vPad comfort / clinical control unit: 8,5 "color touch screen, storage for 1000 programs 2GB Photo Viewer and 4 sintering, cauterization or combipress oven control.

- Technically strong - perfect temperature punctuality for optimum combustion results

- Time-saving, easy operation, low space requirement

- Lacquered steel plate and stainless steel housing

- Table for combustible pieces

- Optical operation display

- With high-quality insulation material equipped combustion chamber

- Combustion chamber made of quartz, temperature sensor

- Automatic temperature calibration before every start

- Temperature accuracy plus / minus 1 ° C

- Excellent bending strength

- It dissolves with difficulty in acids

- The VITA 9 veneering material has similar abrasion as the natural tooth enamel

- With almost all VITA 3D-MASTER and VITA classical A1-D4 material is the color-compatibility ensured

Plastering room

Articulating system

Every technician have an own Amann Girbach Artex articulator. The articulators in the lab are standardized, so the distance of the lower and upper magnetic bases and the relation between the articulator axis and upper magnetic base are the same in all devices. The CAD/CAM scanner's built-in articulator has the same setting as well, but we can change these if requested. On demand, we can also set different articular trajectories as well.

EasyBlast basic-2 (pencil sandblaster)

- LED lighting in the sandblasting chamber

- Easy-to-use, versatile and ergonomic

- Integrated LED lighting, the hand piece can be let optimally, shadow-freely.

- The new EasyBlast can be upgraded to a 4-chamber sandblaster

- 10 times longer lifetime compared to traditional lamps.

- Air consumption approx. 60 l/min

- 3-6 bar pressure

Casting room

In or lab we only use vacuum casting unit with modified atmosphere instead of the earlier centrifugal devices. As a result, the amount of oxide formation has reduced, there are more accurate reabsorption-free castings, and the passive adaptation is faster and more accurate. With precision casting technology, we are able to prepare microscopically accurate frames.

Main equipment

Fornax T (compact induction casting machine)

- High frequency, Centrifugal- induction casting machine

- The high performance induction guarantees short thaw cycles.

- Minimal oxidation during smelting.

- With integrated high performance cooling system, more than 50 casting continuously.

- Low energy consumption (16 ampere)

- Casting temperature even at 1550 0C

- Ideal for every dental alloys (except titanium)

- Due to its compact size and design, the new Fornax T requires very little space.

Korostar plus (The manual blasting unit for crowns, bridges and partial denture work)

- Integrated filter module with quad-filter system.

- High performance sandblasting unit with integrated filter module

- Robust and strong

- The ergonomic design allows relaxed working position and lots os space for comfortable blasting.

- Integrated LED lighting in the chamber ensures precise work

- 10 times longer lifetime compared to traditional lamps.

- Low maintenance cost.

- Reliable even at maximum pressure